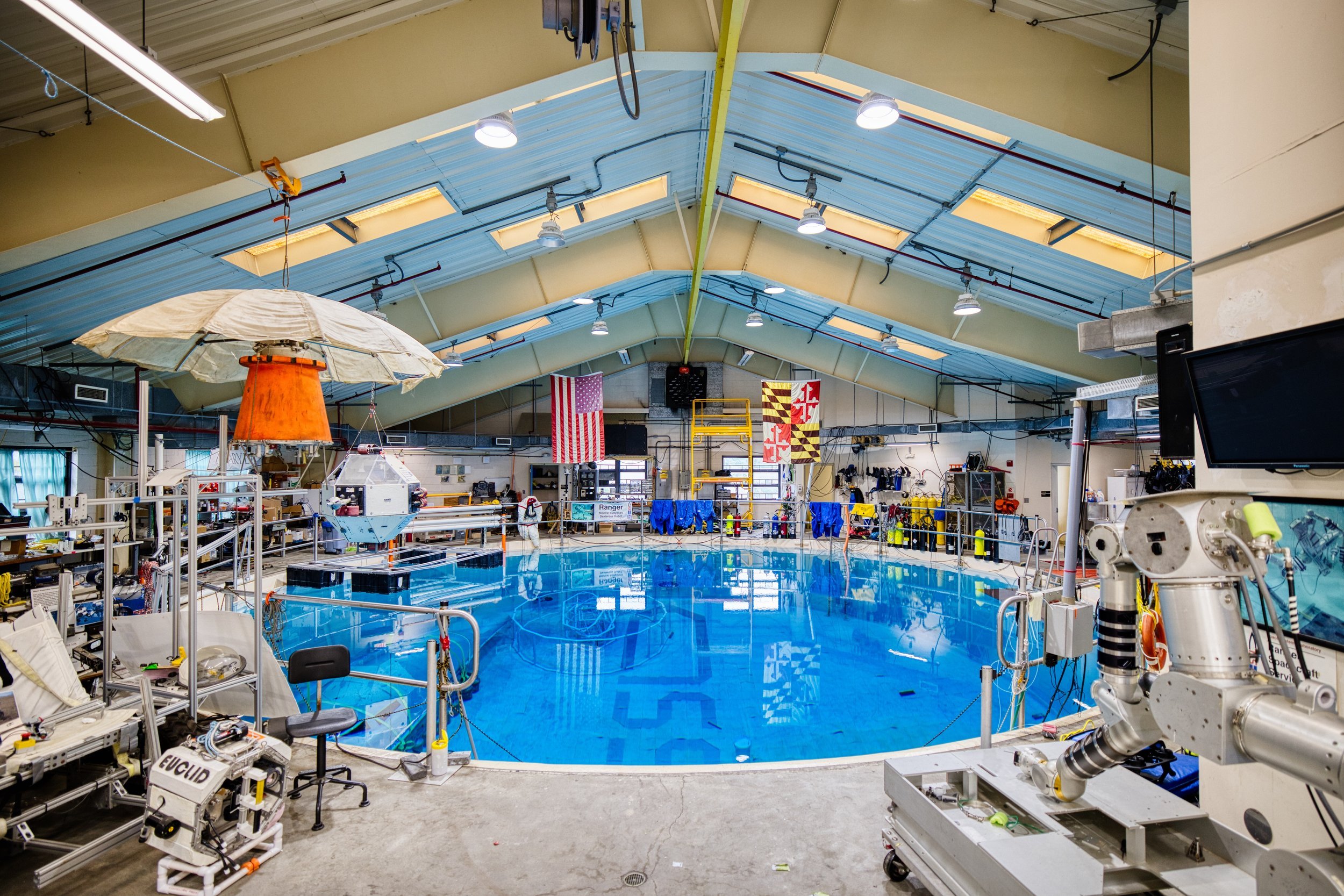

The Only Neutral Buoyancy Research Facility on a University Campus in the World!

The Space Systems Laboratory

It all started when…

At the age of 12 I became an Open Water SCUBA diver after being inspired by documentaries like Planet Ocean and Blue Planet alongside divers in my family. While quarries in the mid-Atlantic region certainly were not as exciting as these documentaries, the experience I gained reaffirmed my appetite for exploration and I soon pursued AOW and Rescue after. After receiving my university acceptance letters in early 2016, choice between schools was all but easy until I stepped inside the Space Systems Laboratory for the first time. I stepped through the high-bay doors of the Neutral Buoyancy Research Facility on an admitted student open house tour, led by a now close friend of mine, and was immediately enamored. So much so, I committed to attend the University of Maryland the same day and became an undergraduate researcher my freshman year, snowballing into graduate research assistantships and now after completing my masters and passing my qualifying and comprehensive exams I am nearing the completion of my doctoral degree.

What makes the NBRF special?

The NBRF is both the largest laboratory space on the University of Maryland campus, and the only neutral buoyancy facility on a university campus in the world housing our 50 foot wide, 25 foot deep tank of 88°F water. Other neutral buoyancy facilities exist in the world within NASA, JAXA, ESA, CNSA, and Roscosmos mostly focused on Extravehicular Activity (EVA) training for astronauts. While the NBRF has performed simulated astronaut activities with both pressurized and unpressurized suits underwater (as seen in some of the gallery photos), in the majority of my time at the facility we have focused on robotic manipulator simulations and habitation. In addition to the 367,000 gallon tank, the NBRF is home to the SSL’s in-house manufacturing facilities where most of our robots are born. Our shop has a wide range of capabilities from sheet metal work to welding, a 4’x4’ AvidCNC Router, Tormach 1100MX, three Bridgeport milling machines, and a Hardinge lathe. In my time at the SSL each machine has found its way into each of my projects. Whether it be tuning in a bearing surface on the lathe, milling actuator housings, or welding rover structures and long robot arms, even though the projects I work on from year to year may change my time in the shop is reliable from year to year.